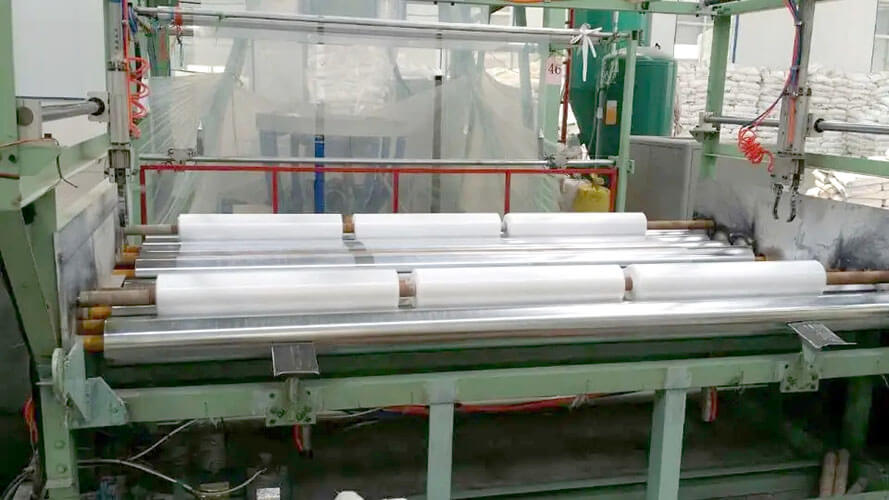

About us

Pioneer of High-end Agricultural Fim Technology in China.

We one of the top 5 manufacturers of agricultural film in China. Since the establishment in 2006, we have devoted to researching and producing high quality but affordable agricultural films for growers all over the world.

Our dedicated R&D team have developed different series of products include:

Long life span anti-fogging series: high efficiency PO film, anti-fog agent coated film, EVA drip-free film.

Films for different crops series: metallocene watermelon film for high altitude area, film for cantaloupe, grapes, kumquat, purple film.

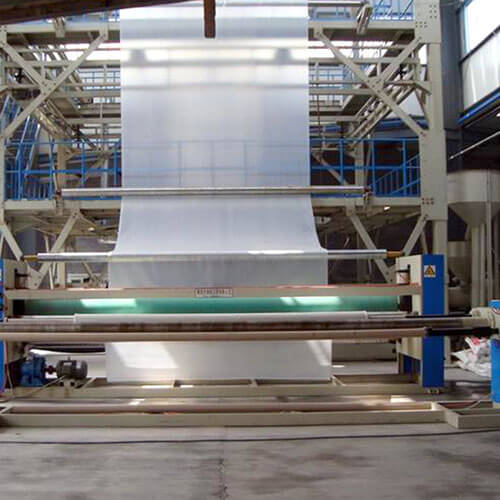

Mulch film series: black, silver/black, bio-degradable films.

We have the unique capability in mixing the different characters and effects based on an area’s climate, crop types farmed, greenhouse types, and other special factor, to engineer the tailor-made films that are best suited to each customer’s requirements.

Datas & Facts

15+

engineers and experts.

19+

Production facilities.

9500+

square meter plant.

180+

tons monthly capacity.

Leading Technologies

PLA + PBAT

Our films are made with PLA and PBAT which is the most appropriate combination for mulch films. PLA, known as polylactic acid is the most widely used degradable material, starch based. PBAT can be bio-degraded and also decomposed. It’s degradability and bio-safety are globally recognized.

PLA (Polylactic Acid, or Polyactide) is a kind of polyester consisting of lactic acid and lactide created by controlled fermentation of a carbohydrate source.

PBAT (Polybutyrate Adipate Terephthalate) is not regarded as a renewable energy source because it is a polymer made from fossil fuels. That said, PBAT is incredibly biodegradable. It completely degrades when buried in soil due to the activity of microorganisms like fungus, algae, and bacteria, and it doesn’t release any methane or dangerous byproducts during this process.

Even more quickly than organic materials like banana peels, PBAT is designed to break down quickly. Contrary to popular belief, the longer it takes to decompose, the higher the percentage of plants. As a result, PBAT and PLA are combined to quicken biodegradation.

Additionally, PLA itself is a brittle, hard substance. In order to increase PLA’s strength and flexibility for the purpose of its intended use, PBAT is added to PLA.

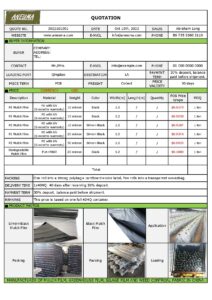

5-Layer Co-extrusion

We are the first company which introduced the 5-layer co-extrusion production equipments in China in 2015.

In the three-layer co-extrusion technology, due to the small number of layers, some different additive functions are mixed in the same layer in the production process, and some additives may affect each other and conflict due to their own structure, so that eventually each function affects the other and cannot play its advantages optimally.

Five-layer co-extrusion technology can add a variety of materials to the resins or additives of different layers, so that multiple layers of materials with different properties can be combined during the extrusion process, and because each layer is independent, there is no mutual influence, so that the product has the excellent properties of a variety of different materials and complement each other’s properties, so that a variety of properties can be combined to achieve the best balance.

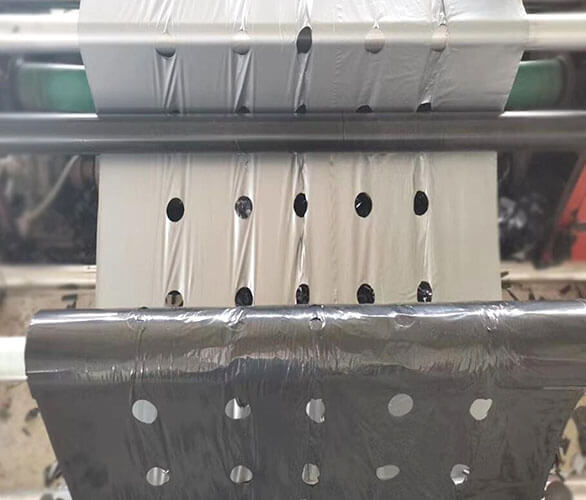

Production Facilities

Get Started Today!

Consult our agricultural film expert and get the best solutions for your agricultural needs.

Benefit from our ever evolving agricultural film technologies, protect your soil, reduce pollutions to environment and crops.

Improve yield and tastes of fruits and vegetables with Aniuma films, receive continous advises from our agronomists.